Titanium Metal Powder bohloeki bo phahameng 99% Spherical Titanium Powder

Tlhaloso ea Sehlahisoa

Titanium phofo ke phofo ea silevera-grey e nang le bokhoni ba ho hema 'me e ka cha tlas'a mocheso o phahameng kapa maemo a spark a motlakase.Sehlahisoa se na le bohloeki bo phahameng, boholo ba likaroloana tse nyenyane le mosebetsi o phahameng oa holim'a metsi.Hangata e sebelisoa sebakeng sa sefofane, ho fafatsa, metallurgy le liindasteri tse ling.

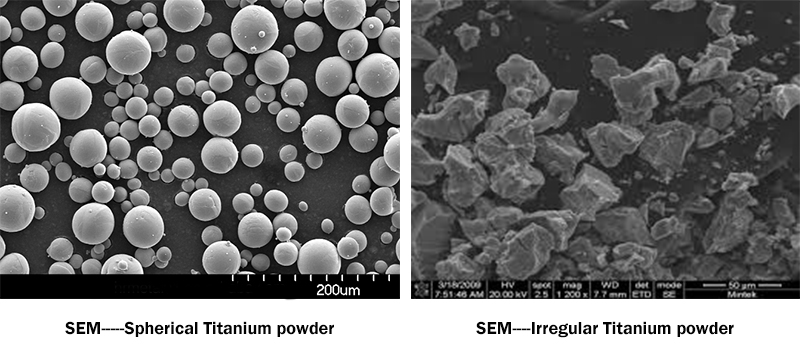

SEM

Tlhaloso

| CPTI --- Sebopeho sa Lik'hemik'hale | |||||||||

| Boholo: | O | N | H | C | Cl | Fe | Si | Mn | Ti |

| -60 | 0.18 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| -80 | 0.2 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| -100 | 0.22 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| -200 | 0.25 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| -325 | 0.32 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.5 |

| -400 | 0.35 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.5 |

| 100-200 | 0.18 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 200-300 | 0.25 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 300-400 | 0.3 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 100-325 | 0.26 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 200-325 | 0.3 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 200-400 | 0.3 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 100-150 | 0.18 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 150-200 | 0.2 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 200-250 | 0.25 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 250-325 | 0.28 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| D50=3μm | 1.8 | 0.035 | 0.04 | 0.03 | 0.04 | 0.04 | 0.02 | 0.01 | 98 |

| D50=5μm | 1.6 | 0.035 | 0.04 | 0.03 | 0.04 | 0.04 | 0.02 | 0.01 | 98 |

| D50=8μm | 1.5 | 0.035 | 0.04 | 0.03 | 0.04 | 0.04 | 0.02 | 0.01 | 98.3 |

| D50=11μm | 1.5 | 0.035 | 0.04 | 0.03 | 0.04 | 0.04 | 0.02 | 0.01 | 98.3 |

| D50=20μm | 1.3 | 0.035 | 0.04 | 0.03 | 0.04 | 0.04 | 0.02 | 0.01 | 98.3 |

Kopo

Sehlahisoa se na le bohloeki bo phahameng, boholo ba likaroloana tse nyenyane le mosebetsi o phahameng oa holim'a metsi.

1.metapo ea phofo

2.methapo ea phofo ea metallurgy.

3. Lisebelisoa tse khethehileng li kenyelletsa li-filters tsa titanium,

4. lisebelisoa tse porous,

5. ho soma lipheo,

6.diamane lisebelisoa

7.polycrystalline diamond.

Molemo oa Huarui Titanium phofo e nang le theknoloji e khethehileng

1.Maemo a tlase a oksijene

2.High sphericity le mokelikeli o babatsehang

3.Less Satellite phofo le phofo e sekoti