Titanium Carbide Powder TiC bakeng sa Carbide ea Cemented

Tlhaloso ea Sehlahisoa

Titanium carbide ke carbide e tsebahalang e thata 'me ke thepa ea bohlokoa e tala bakeng sa tlhahiso ea carbide e entsoeng ka samente.TiC e na le litšobotsi tsa boima bo phahameng ba mocheso, coefficient e nyane ea khohlano le conductivity e tlase ea mocheso, kahoo lisebelisoa tse nang le TiC li na le lebelo le phahameng la ho itšeha le bophelo bo bolelele ba ts'ebeletso ho feta tsa WC le lisebelisoa tse ling.Haeba lesela le tšesaane la TiC le behiloe holim'a sesebelisoa sa lisebelisoa tse ling (joalo ka WC), ts'ebetso ea sesebelisoa e ka ntlafatsoa haholo.

Tlhaloso

| Ntho | HR-19TiC | HR-18TiC | HR-25TiC |

| Kakaretso C. | >19 | 18-19 | 25 |

| FC | <0.4 | <0.2 | <0.2 |

| O | <0.45 | <0.8 | <0.8 |

| <0.6 | |||

| N | <0.4 | <0.45 | <0.45 |

| <0.05 | |||

| Si | <0.08 | <0.08 | <0.08 |

| Na | <0.05 | <0.05 | <0.05 |

| K | <0.05 | <0.05 | <0.05 |

| Al | <0.015 | <0.015 | <0.015 |

| Boholo(FSSS) | 0.5-1um | 0.5-1um | 0.5-1um |

| 1-2 um | 1-2 um | 1-2 um | |

| 2-5um | 2-5um | 2-5um |

Kopo

1. E sebelisoa e le li-additives bakeng sa ho seha lisebelisoa tsa lisebelisoa le tšepe ea bismuth, zinc, cadmium melting crucibles,

2. Tokisetso ea lifilimi tse thibelang ho roala ha semiconductor, lisebelisoa tsa memori tse kholo tsa HDD.

3. Ke karolo ea bohlokoa ea carbide e entsoeng ka samente 'me e sebelisoa e le deoxidizer indastering ea tšepe.

4. E sebelisoa e le cermet, e na le litšobotsi tsa boima bo phahameng, ho hanyetsa kutu le botsitso bo botle ba mocheso.

5. Titanium carbide phofo e ka boela ea sebelisoa ka thepa ea ho fafatsa mocheso e sa keneleng mocheso, lisebelisoa tsa ho tjheseletsa, thepa ea filimi e thata, lisebelisoa tsa lifofane tsa sesole, joalo-joalo.

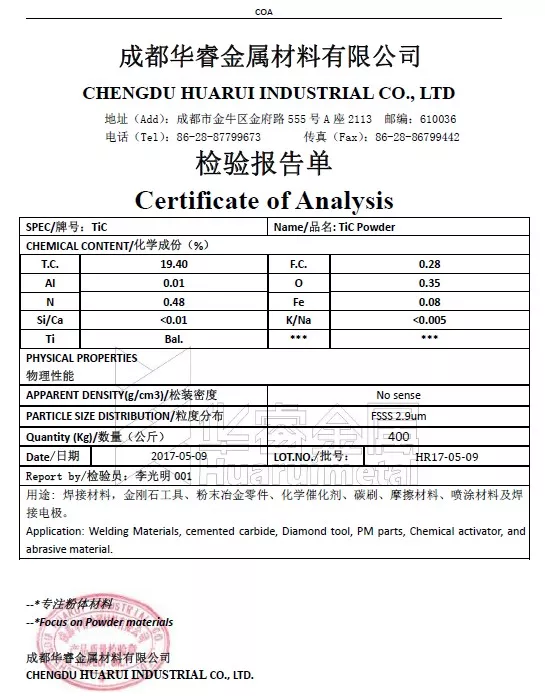

COA

Mokhoa oa ho laola boleng

Huarui e na le sistimi e thata ea taolo ea boleng.Re leka lihlahisoa tsa rona pele ka mor'a hore re qete tlhahiso ea rona, 'me re leka hape pele ho thomello e' ngoe le e 'ngoe, esita le sampole.'Me haeba u hloka, re ka thabela ho amohela motho oa boraro ho etsa tlhahlobo.Ehlile haeba u rata, re ka u fa sampole hore u e hlahlobe.

Boleng ba sehlahisoa sa rona bo netefalitsoe ke Sichuan Metallurgical Institute le Guangzhou Institute of Metal Research.Tšebelisano ea nako e telele le bona e ka boloka nako e ngata ea liteko bakeng sa bareki.