HVOF Wc12Co Tungsten Carbide Cobalt Compound Powder

Tlhaloso ea Sehlahisoa

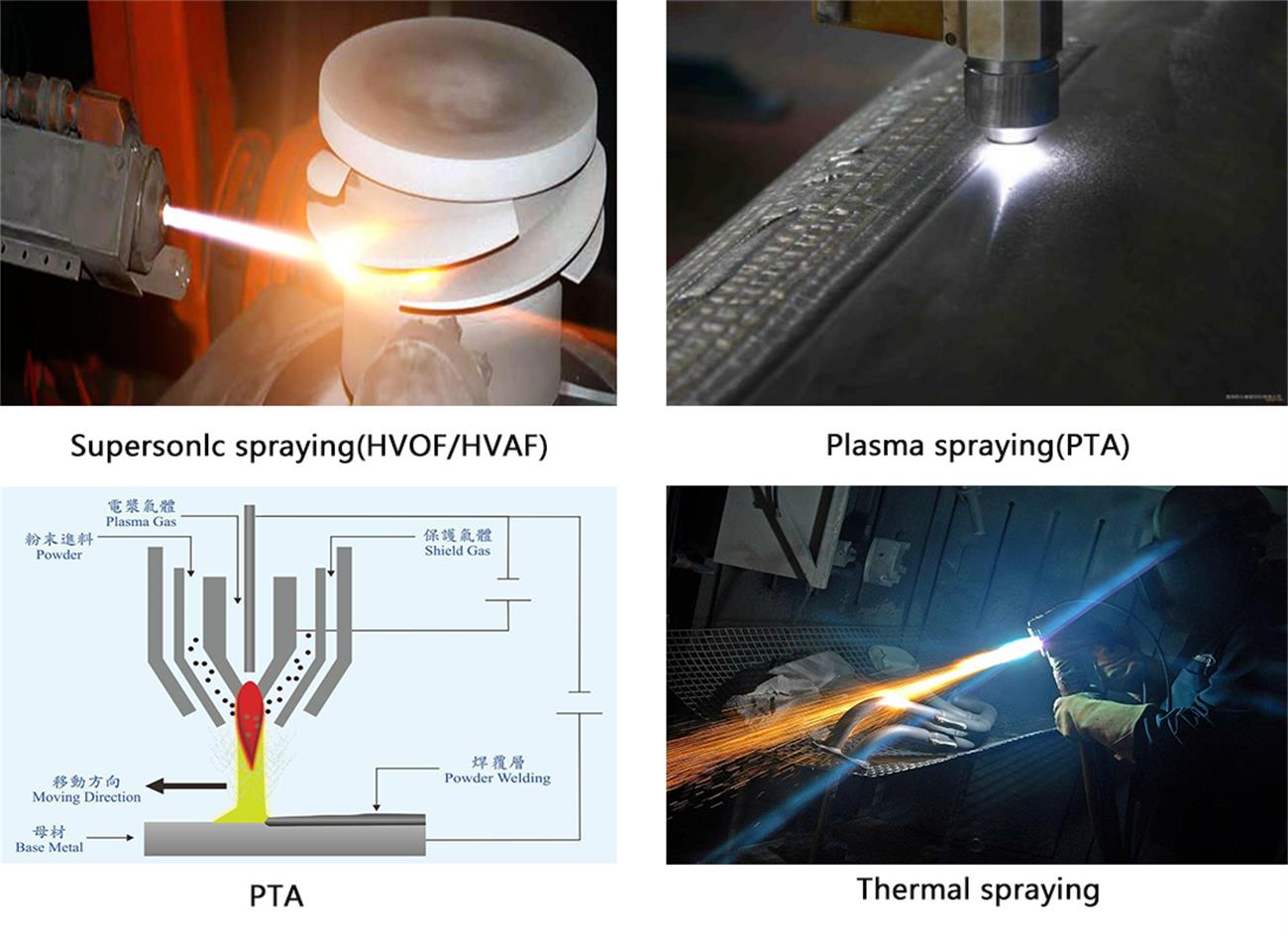

WC Compound powder ke phofshoana e thata-thata ea cobalt, e amohelang mokhoa oa agglomeration le sintering.Ke tšepe ea tšepe ea cobalt e koahetsoeng ka holim'a tungsten carbide bakeng sa tšireletso le tlamahano, e nang le khanyetso e babatsehang ea ho roala le ho senya.Bokhoni ba ho hanela mocheso o phahameng oa oxidation.E loketse ho fafatsa ka plasma kapa mokhoa oa ho fafatsa ka supersonic.Hangata e sebelisoa maemong a nang le matla a ho roala le ho taboha.

Tlhaloso

| Kereiti: | WC-Co | WC-Co | WC-CoCr | Cr3C2-NiCr | WC-CrC-Ni | WC-Ni |

| Mokhoa oa tlhahiso | Agglomerated & Sintered | |||||

| Radio | 88/12 | 83/17 | 86/10/4 | 25/75 | 73/20/7 | 90/10 |

| Kereiti: | boputsoa bo lefifi | boputsoa bo lefifi | boputsoa bo lefifi | |||

| Botenya | 4.3-4.8 | 4.3-4.8 | 4.3-4.8 | 2.3-2.8 | 4.3-4.8 | 4.3-4.8 |

| E tloaelehileng | E tloaelehileng | E tloaelehileng | E tloaelehileng | E tloaelehileng | E tloaelehileng | |

| 4.5 | 4.5 | 4.5 | 2.5 | 4.5 | 4.5 | |

| Ho thatafala | HV | HV | HV | HV | HV | HV |

| 1000/1200 | 850-1050 | 1000/1200 | 700-900 | 1200-1300 | 600-800 | |

| Ho sebetsa hantle ha depositi | 50-70% | 50-70% | 50-70% | 50-60% | 50-60% | 50-60% |

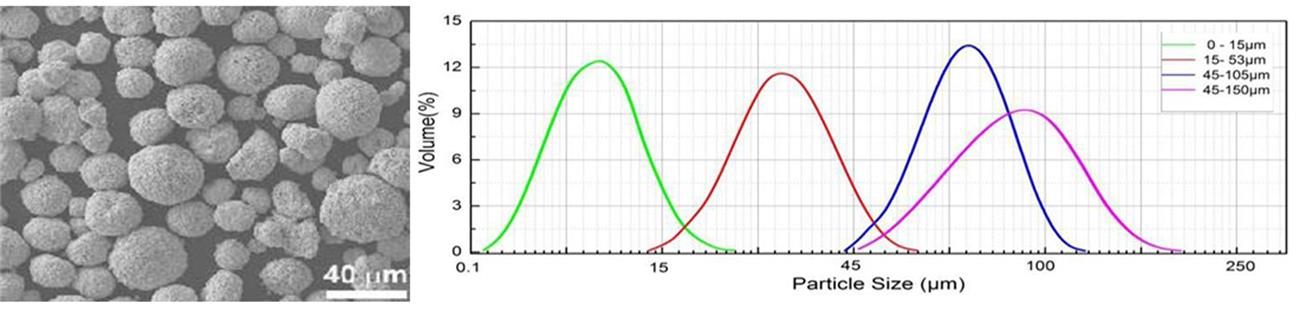

| Boholo | 5-30um | 5-30um | 5-30um | 5-30um | 5-30um | 5-30um |

| 10-38um | 10-38um | 15-45um | 10-38um | 10-38um | 10-38um | |

| 15-45um | 15-45um | 10-38um | 15-45um | 15-45um | 15-45um | |

| 20-53um | 20-53um | 20-53um | 20-53um | 20-53um | ||

| 45-90um | 45-90um | 45-90um | 45-90um | 45-90um | ||

SEM

Kopo

Mokhoa oa ho laola boleng

1.Huarui e na le tsamaiso e tiileng ea tsamaiso ea boleng.Re leka lihlahisoa tsa rona pele ka mor'a hore re qete tlhahiso ea rona, 'me re leka hape pele ho thomello e' ngoe le e 'ngoe, esita le sampole.'Me haeba u hloka, re ka thabela ho amohela motho oa boraro ho etsa tlhahlobo.Ehlile haeba u rata, re ka u fa sampole hore u e hlahlobe.

2.Boleng ba sehlahisoa sa rona bo tiisitsoe ke Sichuan Metallurgical Institute le Guangzhou Institute of Metal Research.Tšebelisano ea nako e telele le bona e ka boloka nako e ngata ea liteko bakeng sa bareki.