3D Printing Nickel Based Alloy Inconel 718 Powder

Tlhaloso ea Sehlahisoa

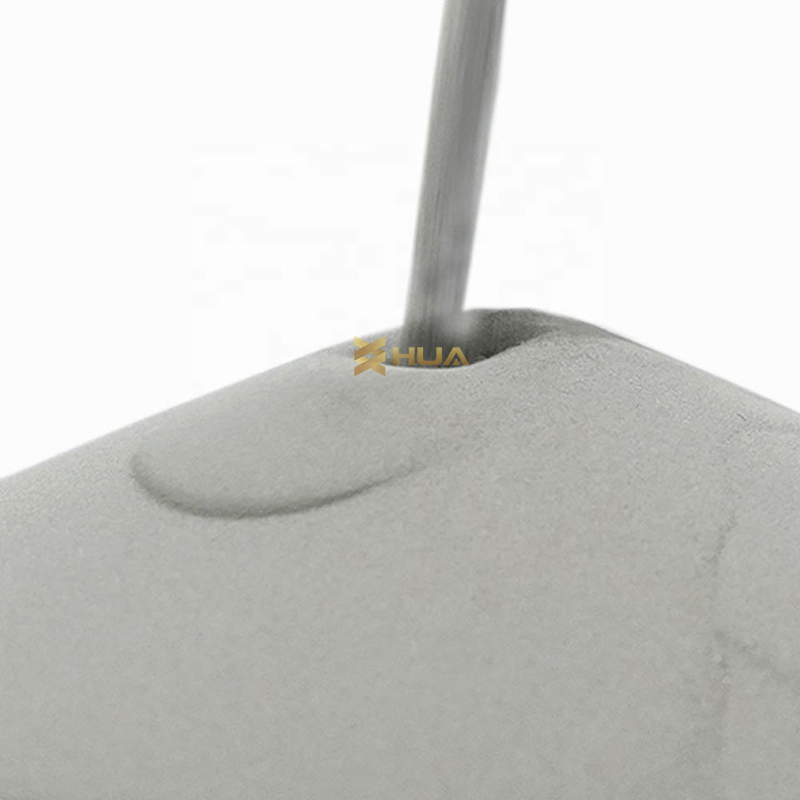

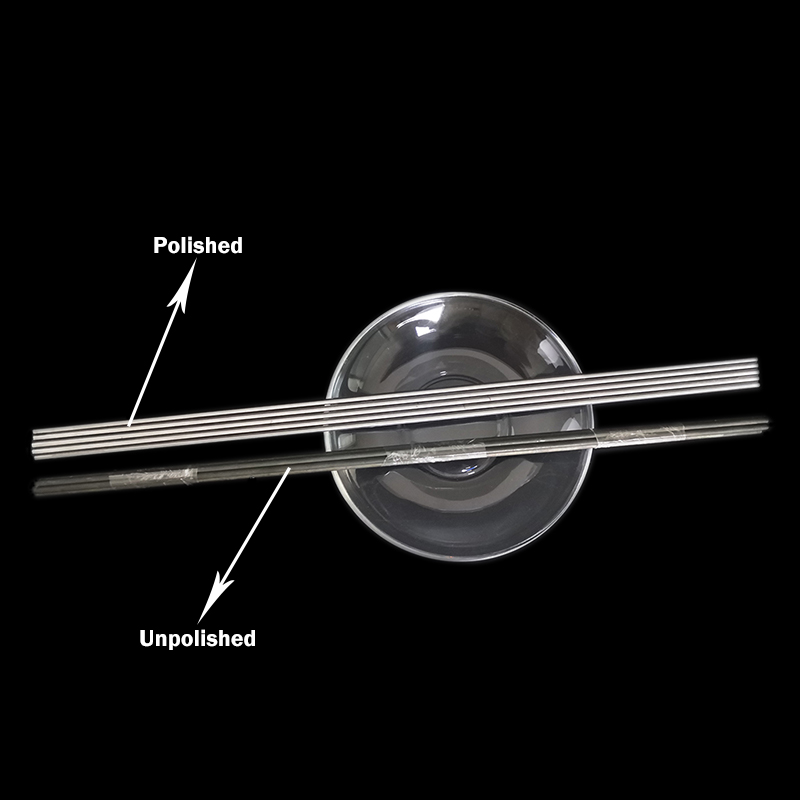

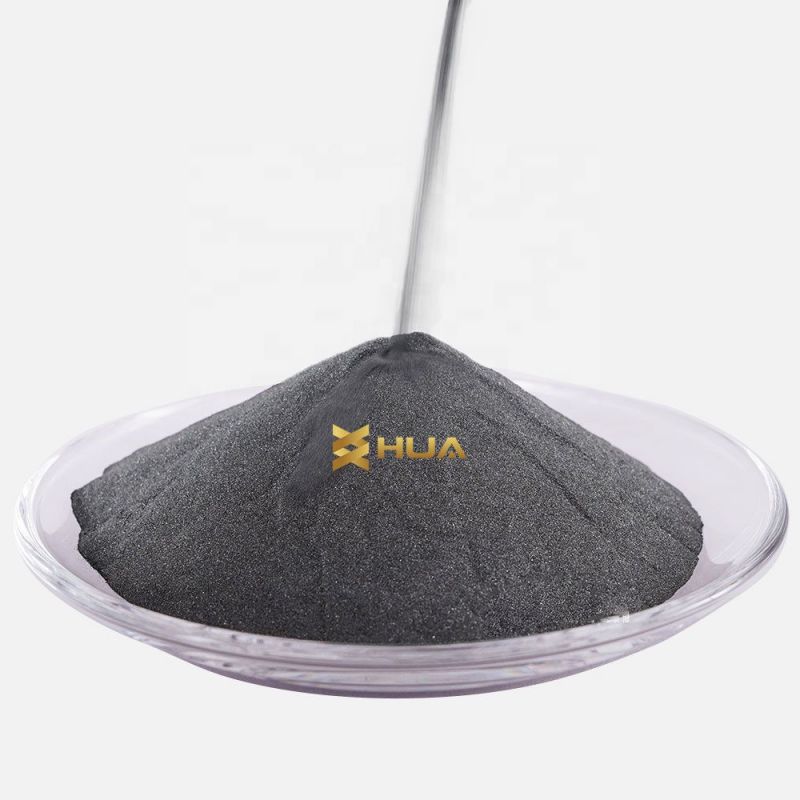

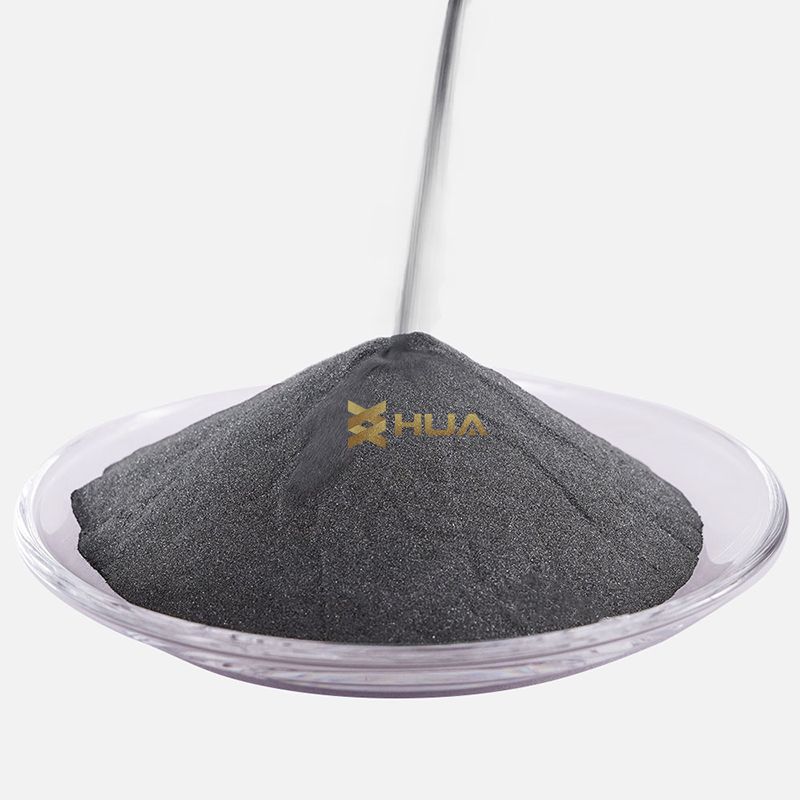

Inconel 718 phofo e na le sphericity e ntle, fluidity, sebaka se tlaase sa ho qhibiliha, mocheso o phahameng oa ho hanyetsa oxidation, ho hanyetsa kutu le ho roala ho hanyetsa.Ka kabo ea boholo ba likaroloana tse fapaneng.Nickel based alloy 718 phofo e ka aroloa ka phofo ea ho bopa ente, phofo ea laser cladding, phofo e fafatsang, phofo e chesang ea isostatic joalo-joalo.

Tlhaloso

| Sebopeho sa Lik'hemik'hale (%) sa Inconel 718 Powder | |||||||

| C | Mn | Si | P | S | Cr | Co | Mo |

| ≤0.08 | ≤0.35 | ≤0.35 | ≤0.015 | ≤0.015 | 17-21 | ≤1.0 | 2.8-3.3 |

| Nb+Ta | Ti | Al | Fe | Cu | Ni | N | |

| 4.75-5,5 | 0.65-1.15 | 0.2-0.8 | Bal | ≤0.03 | 50-55 | ≤0.006 | |

| Inconel 718 Thepa ea Phofo | |||||

| Boholo Range | 0 ~ 25um | 0 ~ 45um | 15 ~ 45um | 45 ~ 105um | 75-180 limilimithara |

| Morphology | Spherical | Spherical | Spherical | Spherical | Spherical |

| PSD (Kabo ea boholo ba karolo) | D10: 6m | D10: 9m | D10:14um | D10:53um | D10:78um |

| D50:16um | D50:28um | D50:35um | D50: 69um | D50: 120um | |

| D90:23um | D90:39um | D90:45um | D90: 95um | D90: 165um | |

| Bokhoni ba ho phalla | N/A | ≤30S | ≤28S | ≤16S | ≤18S |

| Boima bo hlakileng | 4.2g/cm3 | 4.5g/cm3 | 4.4g/cm3 | 4.5g/cm3 | 4.4g/cm3 |

| Litaba tsa Oksijene (wt %) | O: 0.06~0.018wt% , ASTM standard : ≤0.02 wt% | ||||

| 3D printing Gas Atomized Inconel 718 Powder ka theko e ntle ka ho fetisisa | |||||

| (oksijene e tlase, sphericity e phahameng le phallo e ntle) | |||||

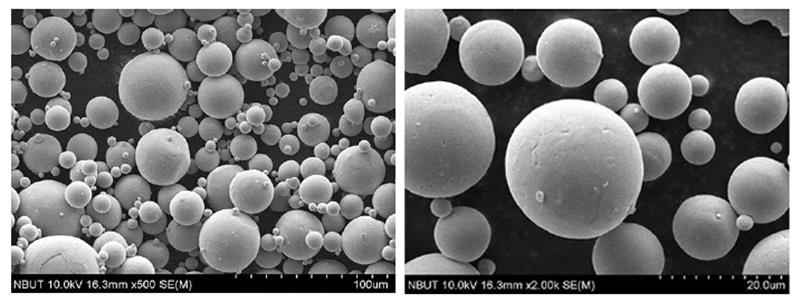

SEM

Kopo

1. HVOF

2. Ho roala ka plasma

3. Khatiso ea 3D

4. tjheseletsa phofo

5. ho bopa ente ea tšepe

6. isostatic e chesang

Mokhoa oa ho laola boleng

Huarui e na le sistimi e thata ea taolo ea boleng.Re leka lihlahisoa tsa rona pele ka mor'a hore re qete tlhahiso ea rona, 'me re leka hape pele ho thomello e' ngoe le e 'ngoe, esita le sampole.'Me haeba u hloka, re ka thabela ho amohela motho oa boraro ho etsa tlhahlobo.Ehlile haeba u rata, re ka u fa sampole hore u e hlahlobe.

Boleng ba sehlahisoa sa rona bo netefalitsoe ke Sichuan Metallurgical Institute le Guangzhou Institute of Metal Research.Tšebelisano ea nako e telele le bona e ka boloka nako e ngata ea liteko bakeng sa bareki.