alsi10mg phofo

Tlhaloso ea Sehlahisoa

Huarui e etsa metsi a sebetsang hantle le khase ea Aluminium Silicon Powder e ntlafalitsoeng bakeng sa tlhahiso ea tlatsetso (khatiso ea 3D, prototyping e potlakileng).Li-powders tsa rona tsa tšepe tse chitja tse sa phallang li entsoe hore li se ke tsa e-ba le agglomerate tse nang le oksijene e tlaase haholo le carbon content, micro-structure e tsitsitseng le morphology e laoloang ka thata le kabo ea boholo ba likaroloana tse nolofalletsang tlhahiso ea mehaho e meholo e rarahaneng ntle le ho tela botšepehi ba thepa.

Tlhaloso

| Aluminium e thehiloeng Alloy Powder | |||||

| Alloy Grades | Alloy Grades | Khemistri | ASTM | ||

| HR10Mg | ZL104 AlSi10Mg | AlSi10Mg CL31Al | Si 9.0-11.0 Fe 0.55 max 0.45 max Mg 0.2-0.45 | Zn 0.10 max Ke 0.05 max Ke 0.15 max Al Bal | A03600 |

| HR10Mg | ZL102 AlSi12 | Al oxide 0.8 max Ke 0.30 Fe 0.80 Mg 0.15 | Mohl 0.15 Lits'oants'o 11-13 Zn 0.20 Al Bal | ||

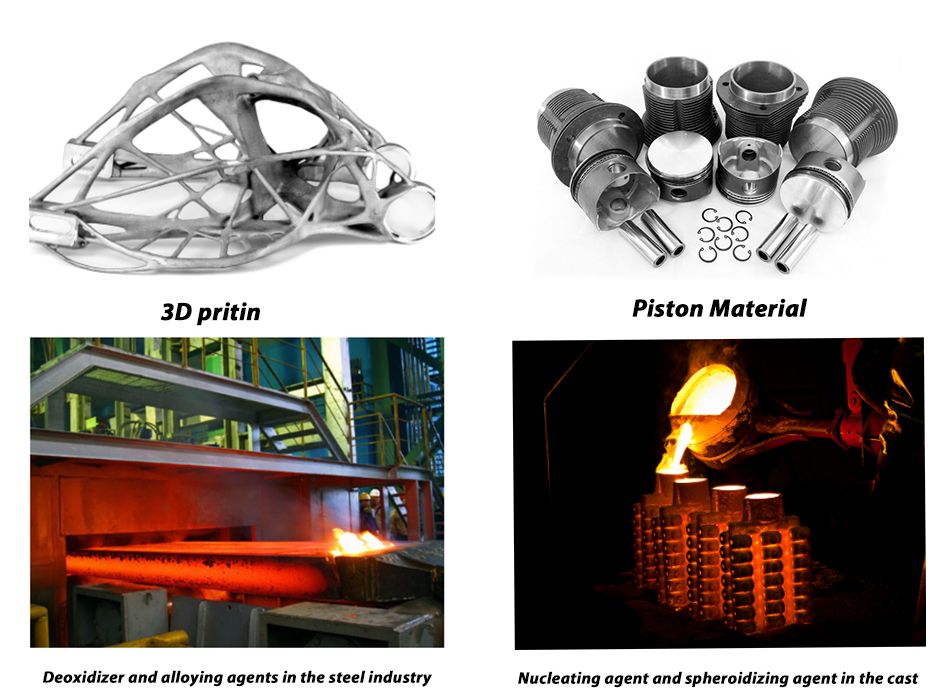

Kopo

1.Elektroniki Packaging Materials

2. Joaloka li-deoxidizer le li-alloying agents indastering ea tšepe.

3.Piston Material

4.E le moemeli oa nucleating le spheroidizing agent indastering ea tšepe ea tšepe.

5.Lisebelisoa tse tsamaisang

6.E le ho fokotsa tlhahiso ea ferroalloy.

7.Aluminium brazing

8. Khatiso ea 3D

Mokhoa oa ho laola boleng

Huarui e na le sistimi e thata ea taolo ea boleng.Re leka lihlahisoa tsa rona pele ka mor'a hore re qete tlhahiso ea rona, 'me re leka hape pele ho thomello e' ngoe le e 'ngoe, esita le sampole.'Me haeba u hloka, re ka thabela ho amohela motho oa boraro ho etsa tlhahlobo.Ehlile haeba u rata, re ka u fa sampole hore u e hlahlobe.

Boleng ba sehlahisoa sa rona bo netefalitsoe ke Sichuan Metallurgical Institute le Guangzhou Institute of Metal Research.Tšebelisano ea nako e telele le bona e ka boloka nako e ngata ea liteko bakeng sa bareki.