NiCr Nickel Chromium Based Alloy phofo bakeng sa Thermal Spray

Tlhaloso ea Sehlahisoa

Nickel-chromium alloy powder e na le khanyetso e ntle ea mocheso o phahameng oa oxidation, ho roala ho ka sebetsa ka mocheso o ka tlase ho 980 ℃, 'me ho roala ho na le ho tiea ho hotle le ho sebetsa hantle.E loketse mekhoa eohle ea ho fafatsa le lisebelisoa, haholo-holo e sebelisoang e le tšireletso ea tšireletso bakeng sa likarolo tsa tšepe le likarolo tse tlaase tsa alloy tlas'a maemo a phahameng a mocheso, hape e ka sebelisoa e le mohato o tlamang bakeng sa ho roala carbide.Mocheso o qhibilihang oa phofo: 1400-1550 ℃, phallo ea 18-23 sec/50g

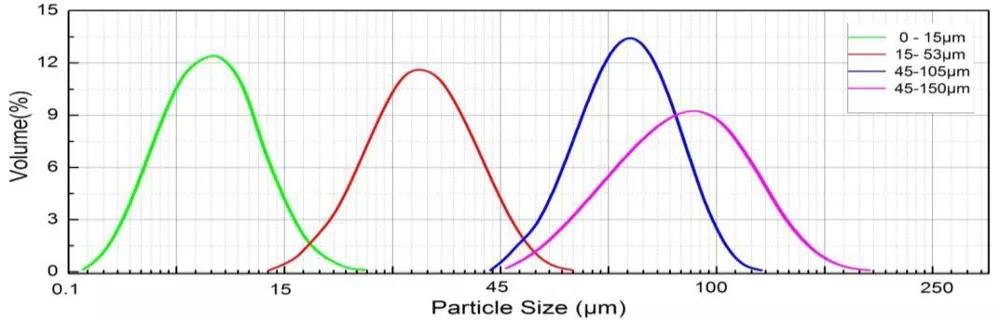

Tlhaloso

| NiCr alloy e entsoe ka atomo | Khemistri | Phallo Density | Boholo | Ho thatafala | Lintlha tsa Kopo |

| N:80 Likr:20 | 17-21 s/50g 4.2-4.5 g/cm3 | 105-45um -53+15um | 10HRC | E hanela mocheso o phahameng.Oxidizing le likhase tse senyang, li thibela scalingon carbon le low alloy steels Bondcoat e ntle bakeng sa lijase tse ka holimo tsa ceramic Chromium e phahameng e ntlafatsa ho hanyetsa ho bola Sputtering Target powder ka boeona kapa e le bond coatTšebeletso ea ho fihla ho 980°C (1,800 °F) |

PS: Re boetse re fana ka litšebeletso tse ikhethileng

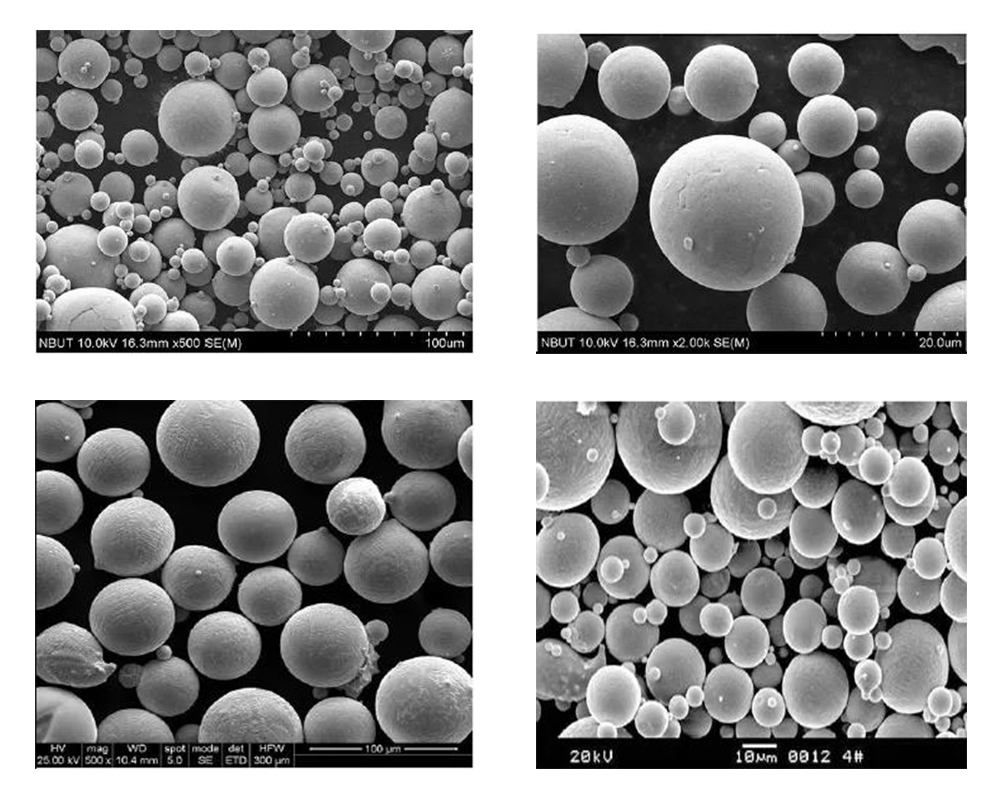

SEM

Monyetla oa HUARUI atomized nickel chrome alloy powder bakeng sa spray ea mocheso

●Sphericity e phahameng Khase e tlase

● Ho phalla hantle

● phofo e nyenyane e sekoti, phofo e nyenyane ea sathelaete

● Matla a phahameng a bond, le porosity e tlase

Mokhoa oa ho laola boleng

1.Huarui e na le tsamaiso e tiileng ea tsamaiso ea boleng.Re leka lihlahisoa tsa rona pele ka mor'a hore re qete tlhahiso ea rona, 'me re leka hape pele ho thomello e' ngoe le e 'ngoe, esita le sampole.'Me haeba u hloka, re ka thabela ho amohela motho oa boraro ho etsa tlhahlobo.Ehlile haeba u rata, re ka u fa sampole hore u e hlahlobe.

2.Boleng ba sehlahisoa sa rona bo tiisitsoe ke Sichuan Metallurgical Institute le Guangzhou Institute of Metal Research.Tšebelisano ea nako e telele le bona e ka boloka nako e ngata ea liteko bakeng sa bareki.