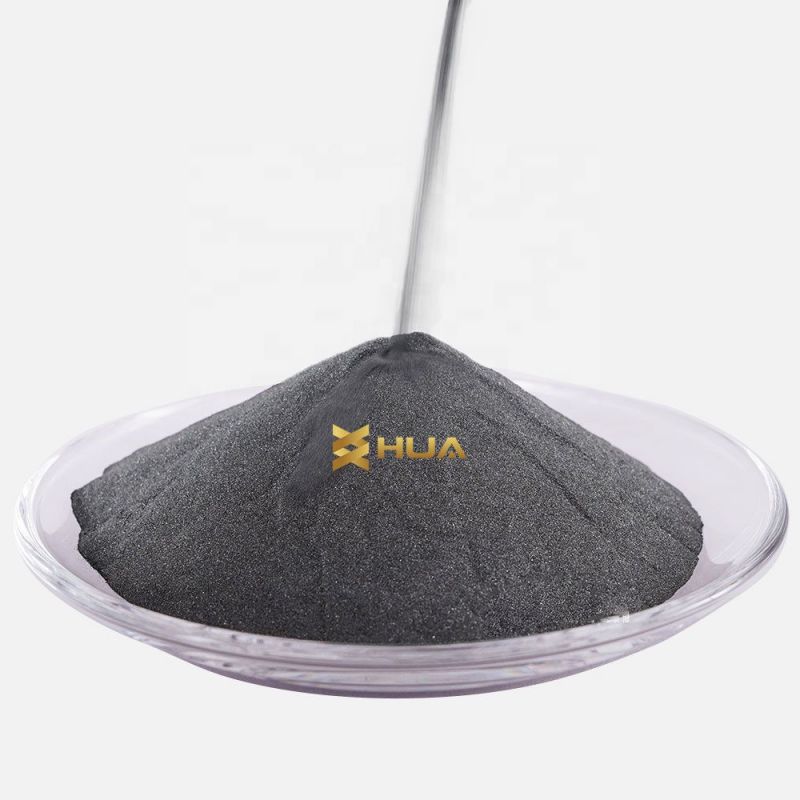

Metal alloy titanium powder ti6al4v phofo bakeng sa khatiso ea 3d

Tlhaloso ea Sehlahisoa

Ti6Al4V phofo e bitsoang TC4, ke α-β titanium alloy e nang le karo-karolelano e phahameng ea matla le boima ba 'mele le ho hanyetsa ho hotle ha kutu.Ke e 'ngoe ea li-alloys tsa titanium tse sebelisoang ka ho fetisisa' me e sebelisoa haholo ka sekhahla se tlaase 'me ho hanyetsa ha kutu hoa hlokahala bakeng sa indasteri e joalo ea sefofane le lisebelisoa tsa biomechanical (li-implants le li-prostheses) .Ti6Al4V e nkoa e le "motheo" oa indasteri ea titanium. hobane ke motsoako o sebelisoang haholo ho fetisisa oa titanium, ho feta 50% ea kakaretso ea titanium.

TC4 titanium alloy e na le khanyetso e ntle ea kutu.E na le letoto la melemo e kang boima bo tlase, matla a khethehileng a phahameng, ho tiea hantle, ho cheseha hantle joalo-joalo.E 'nile ea sebelisoa ho aerospace, petrochemical, shipbuilding, koloi, meriana le liindasteri tse ling.

Lintlha tse qaqileng

| Sebopeho sa phofo ea titanium nitride | |||

| Ntho | TiN-1 | TiN-2 | TiN-3 |

| Bohloeki | >99.0 | >99.5 | >99.9 |

| N | 20.5 | >21.5 | 17.5 |

| C | <0.1 | <0.1 | 0.09 |

| O | <0.8 | <0.5 | 0.3 |

| Fe | 0.35 | <0.2 | 0.25 |

| Botenya | 5.4g/cm3 | 5.4g/cm3 | 5.4g/cm3 |

| boholo | <1micron 1-3micron | ||

| 3-5micron 45micron | |||

| katoloso ya mocheso | (10-6K-1): 9.4 phofo e lefifi / e mosehla | ||

Tlhaloso

| Titanium aluminium alloy(TC4) phofo ea thepa | |||||

| Boholo Range | 0-25um | 0-45um | 15-45um | 45-105um | limithara tse 75-180 |

| Morphology | Spherical | Spherical | Spherical | Spherical | Spherical |

| PSD-D10 | 7um | 15um | 20um | 53um | 80um |

| PSD-D50 | 15um | 34um | 35um | 72um | 125um |

| PSD-D90 | 24um | 48um | 50um | 105um | 200um |

| Bokhoni ba ho phalla | N/A | ≤120S | ≤50S | ≤25S | 23S |

| Boima bo hlakileng | 2.10g/cm3 | 2.55g/cm3 | 2.53g/cm3 | 2.56g/cm3 | 2.80g/cm3 |

| Litaba tsa Oksijene(wt%) | O: 0.07-0.11wt%, maemo a ASTM:≤0.13wt% | ||||

Re boetse re fana ka litšebeletso tse ikhethileng

Welcom ho hloka COA & sampole ea mahala bakeng sa Teko

SEM

| Titanium aluminium alloy(TC4) phofo Lintho tse ka sehloohong: | ||

| Al | V | Ti |

| 5.50-6,75 | 3.50-4,50 | Bal |

Kopo

1. tlhahiso ea laser / electron beam (SLM / EBM).

2. phofo ea metallurgy (PM) le mekhoa e meng.

3. mefuta e sa tšoaneng ea khatiso ea tšepe ea 3D, ho akarelletsa Renishaw, Renishaw, Jeremane EOS (EOSINT M series), Concept Laser, 3D systems le lisebelisoa tse ling tsa laser melting.

4. ho etsoa ha likarolo tsa sefofane, Li-Aeroengine Blades le likarolo tse ling tsa mosebetsi oa ho lokisa.

5. thepa ea bongaka.