IN625 Nickel Base Alloy Powder Inconel 625 Powder

Tlhaloso ea Sehlahisoa

Huarui mocheso o phahameng oa nickel-based alloy IN625 phofo ke phofo e ntlafalitsoeng, haholo-holo e loketseng theknoloji ea ho etsa SLM, ho akarelletsa le EOS Selective Laser Melting Equipment (EOSINT M Series), Concept Laser Melting Equipment, Renishaw Laser Melting Equipment, American 3D Systems Laser Melting Equipment, le litsi le litsi tsa lipatlisiso tsa malapeng.

Ka kabo ea boholo ba likaroloana tse fapaneng, e ka aroloa ka phofo ea ente, phofo ea laser cladding, phofo e fafatsang, phofo e chesang ea isostatic joalo-joalo.

Tlhaloso

| Sebopeho sa Lik'hemik'hale (%) sa Inconel 625 Powder | ||||||

| Cr | Co | Al | Mo | Mn | Ti | Nb |

| 20-23 | ≤1.0 | ≤0.4 | 8.0-10 | ≤0.5 | ≤0.4 | 3.15-4.15 |

| Fe | C | Si | P | S | O | Ni |

| ≤0.5 | ≤0.1 | ≤0.5 | ≤0.015 | ≤0.15 | ≤0.02 | Bal |

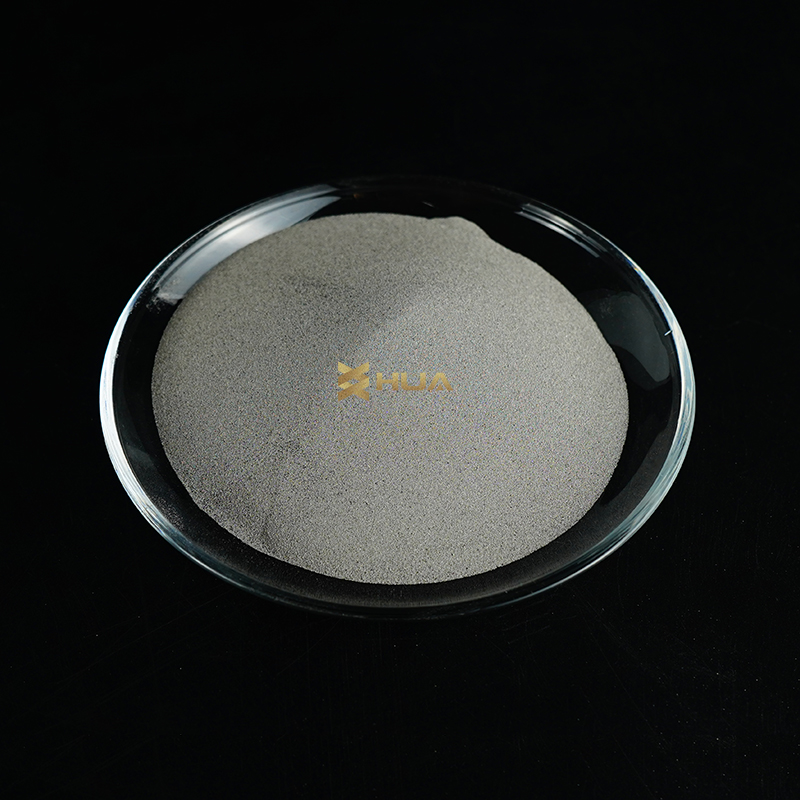

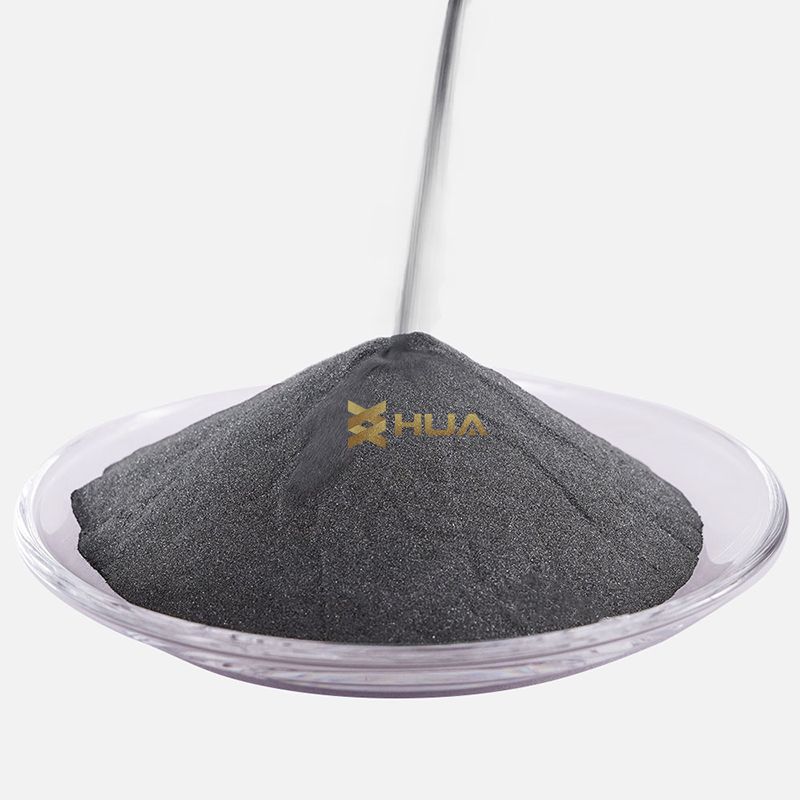

| Boima bo bonahalang: 4.50g/cm3 | Mmala: bohlooho | Sebopeho: se chitja | ||||

| Boholo ba Karolo | 15-53micron;45-105micron;45-150micron | |||||

| Inconel 625 Thepa ea Phofo | ||||||

| Boholo Range | 0 ~ 25um | 0 ~ 45um | 15 ~ 45um | 45 ~ 105um | 75-180 limilimithara | |

| Morphology | Spherical | Spherical | Spherical | Spherical | Spherical | |

| Kabo ea boholo ba Particle | D10: 6m | D10: 9m | D10:14um | D10:53um | D10:78um | |

| D50:16um | D50:28um | D50:35um | D50: 69um | D50: 120um | ||

| D90:23um | D90:39um | D90:45um | D90: 95um | D90: 165um | ||

| Bokhoni ba ho phalla | N/A | ≤30S | ≤28S | ≤16S | ≤18S | |

| Boima bo hlakileng | 4.2g/cm3 | 4.5g/cm3 | 4.4g/cm3 | 4.5g/cm3 | 4.4g/cm3 | |

| Litaba tsa Oksijene (wt %) | O: 0.06~0.018wt% , ASTM standard : ≤0.02 wt% | |||||

| 3D printing Gas Atomized Inconel 625 Powder ka theko e ntle ka ho fetisisa | ||||||

| (oksijene e tlase, sphericity e phahameng le mokelikeli o motle) | ||||||

Kopo

1. HVOF

2. Ho roala ka plasma

3. Ho hatisoa ha 3D / ho eketsa tlhahiso

4. tjheseletsa phofo

5. ho bopa ente ea tšepe

6. isostatic e chesang

Lihlahisoa tse Amanang

Re boetse re fana ka phofo ea Inconel 718, phofo ea NiCr, phofo ea NiAl, phofo ea Ni20-Ni65, re amohelehile ho botsa!