B4C nanopowder Boron carbide phofo bakeng sa thepa ea ho tjheseletsa

Tlhaloso ea Sehlahisoa

Micropowder Black B4C Boron Carbide Powder Bakeng sa Coating ea Ceramic

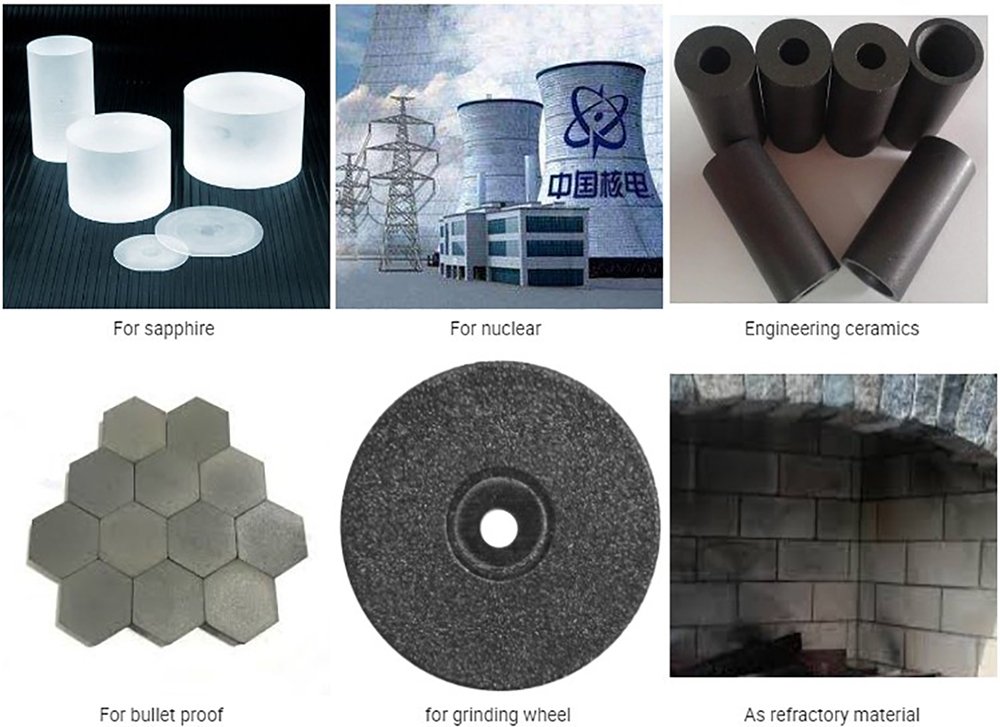

Boron carbide, e leng daemane e ntšo, hangata ke phofo e mebala. Ke e 'ngoe ea lintho tse tharo tse thata ka ho fetisisa tse tsejoang (tse ling tse peli ke taemane le cubic boron nitride)' me e sebelisoa ho lihlomo tsa tanka, lisutu tse thibelang likulo le lisebelisoa tse ngata tsa indasteri.E sebelisoa ka thepa e sa sebetseng, mohato o matlafalitsoeng oa ceramic, haholo-holo lihlomong tse bobebe, monyetla oa neutron oa reactor, e.tc.

| Lebitso le leng | B2-C,B4C,daemane e ntsho,teraboron carbide |

| CAS NO. | 12069-32-8 |

| Foromo ea lik'hemik'hale | B4C |

| Boima ba Molar | 55.255 g mol |

| Ponahalo | Phofo e ntšo |

| Botenya | 2.52g/cm(e tiileng) |

| Sebaka se qhibilihang | 2350°C (2623.15 K) |

| Ntho e belang | >3500°C (>3773.15 K) |

| Ho qhibiliha ka metsing | E sa qhibidihang |

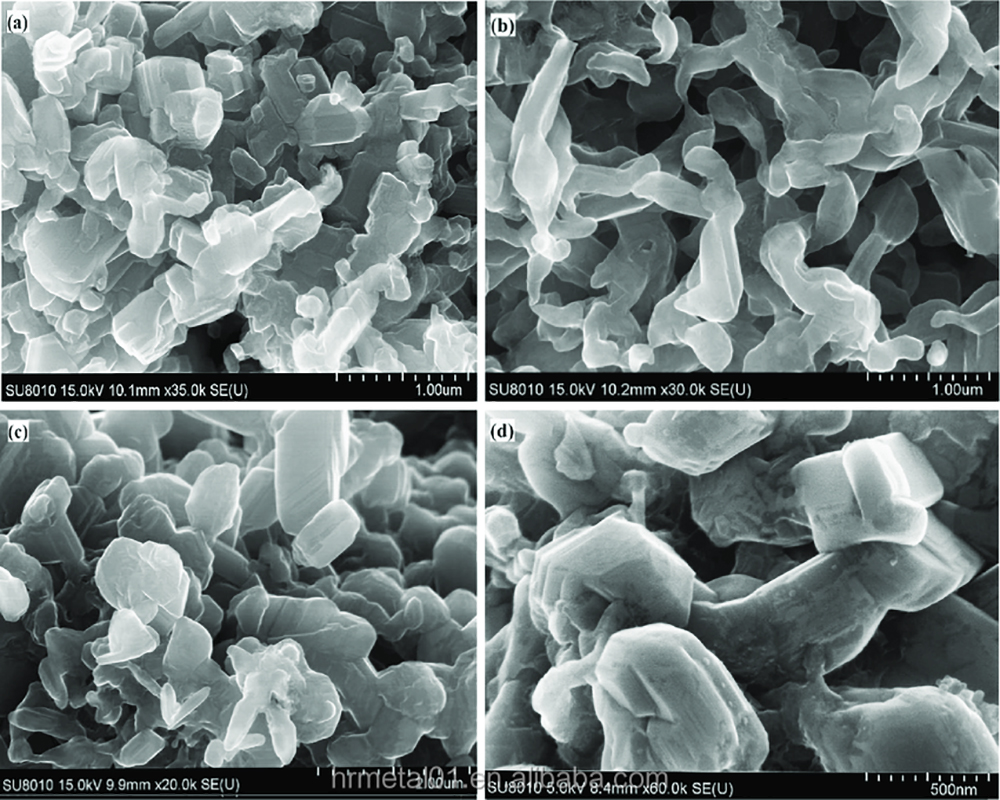

| Sebopeho sa kristale | rhombohedral |

| Kotsi e ka sehloohong | Harfu, Ho khopisa |

Lintlha tse qaqileng

| Grit Size | Boholo | Sebopeho sa Lik'hemik'hale | |||

| B% | C% | Fe2O3% | BC% | ||

| 60# | 315-215 | 78-81 | 17-22 | 0.2-0.4 | 97-99 |

| 80# | 200-160 | ||||

| 100# | 160-125 | ||||

| 120# | 125-100 | 78-80 | 17-22 | 0.2-0.4 | 96-98 |

| 150# | 100-80 | ||||

| 180# | 80-63 | ||||

| 240# | 60-50 | 77-80 | 17-22 | 0.3-0.5 | 96-97 |

| 280# | 50-40 | ||||

| 320# | 40-28 | ||||

| W40(360#) | 35-28 | 76-79 | 17-21 | 0.3-0.6 | 95-97 |

| W28(400#) | 28-20 | ||||

| W20(500#) | 20-14 | 75-79 | 17-21 | 0.4-0.8 | 94-96 |

| W14(600#) | 14-10 | ||||

| W10(800#) | 10-7 | 74-78 | 17-21 | 0.4-0.9 | 92-94 |

| W7(1000#) | 7-5 | ||||

| W5(1200#) | 5-3,5 | 74-78 | 17-21 | 0.5-0.9 | 90-93 |

| W3.5(1500#) | 3.5-2,5 | ||||

| -325# | <45 | 74-79 | 17-22 | <0.3 | 92-97 |

| 0-44μm | <45 | ||||

| -200# | <90 | 74-80 | 17-22 | <0.3 | 94-97 |

| -100# | <150 | ||||

| 0-25μm | <25 | 74-79 | 17-21 | <0.3 | 92-96 |

| 0-10μm | <10 | 74-78 | 17-21 | <0.3 | 91-95 |

| 60#-150# | 250-75 | 77-81 | 17-22 | <0.3 | 95-98 |

| 40#-120# | 315-106 | ||||

| 30#-60# | 355-250 | ||||

| Boron carbide | 355-250 | 92-80 | 17-23 | <0.3 | 90-99 |

SEM

Sephutheloana

Molemo

1. Lisebelisoa tsa ho sila tsa likaroloana tse phahameng;

2. Etsa lik'hemik'hale tsa ceramic, khalase, kapa nozzle;

3. Reactor ea nyutlelie le thepa e sireletsang;

4.Hlahisa lihlomo tse thibelang likulo;

5. Ntlafatsa phahamiso ea litšebeletso tsa likarolo tsa mochini;

6. E le tlatsetso e tlatsang bakeng sa lisebelisoa tsa lik'hemik'hale tsa boron;

7. Essential filler bakeng sa thepa refractory.