Phofo e Ekelitsoeng ea Tlhahiso ea Stainless Steel Powder 316l bakeng sa Khatiso ea 3d

Tlhaloso ea Sehlahisoa

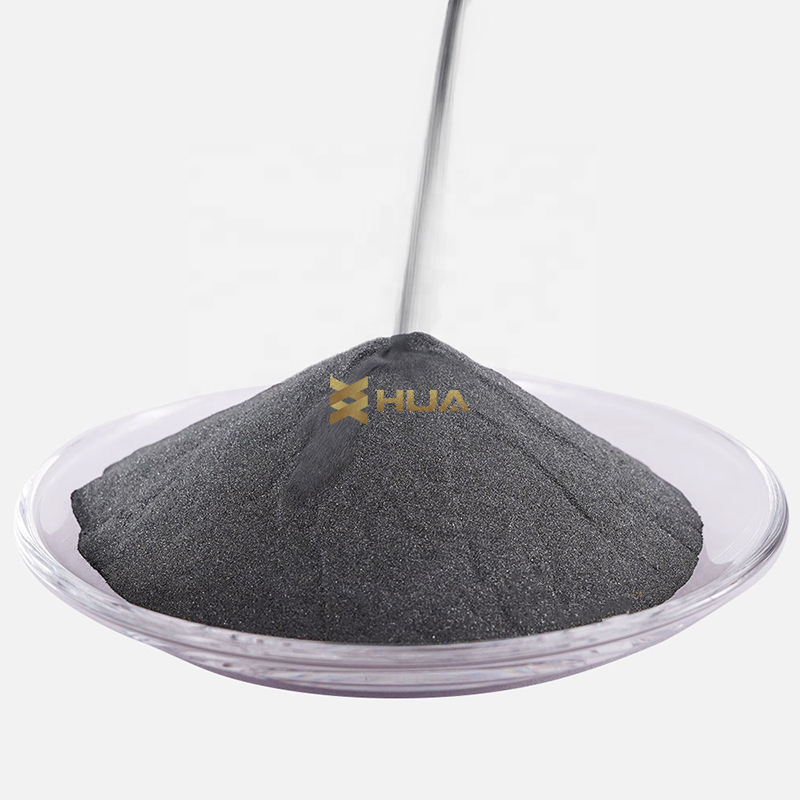

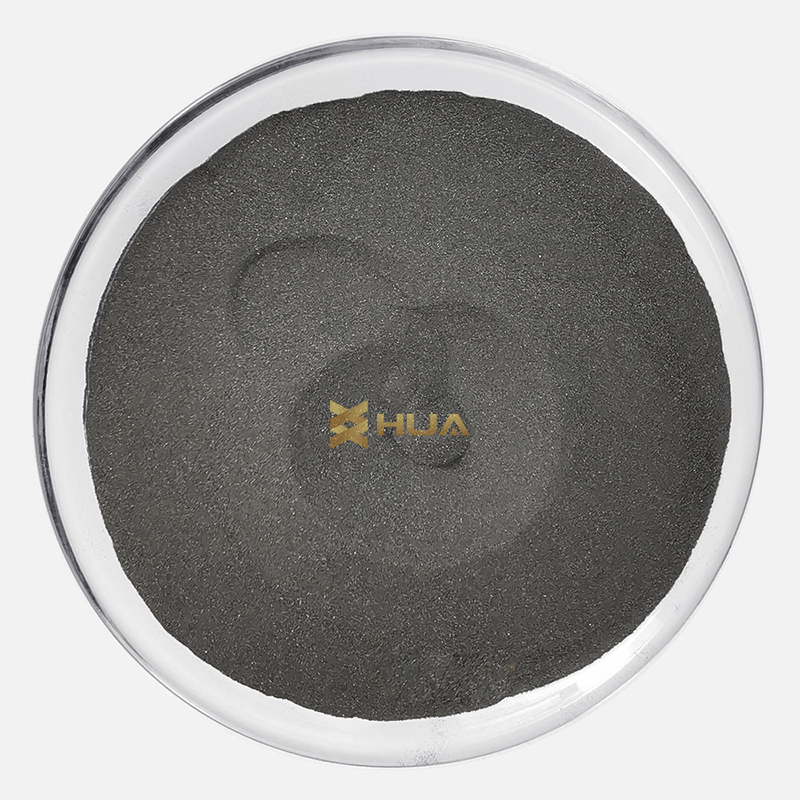

Phofo ea tšepe e sa hloekang e entsoe ka ts'ebetso ea atomization ea metsi mme e na le khanyetso e ntle ea kutu le ho tšoarella.Phofo ea tšepe e sa hloekang e na le mefuta e mengata ea tšebeliso ea indasteri.

Fana ka mefuta e fapaneng ea phofo ea tšepe e sa hloekang ka boholo bo fapaneng.

Ho latela tšebeliso

1.Hot Isostatic Pressing

2.Metal Ente Molding

3.3D khatiso

4.Ho fafatsa ka mocheso

Ho latela mokhoa oa tlhahiso

1.Metsi atomization

2.Khase ea metsi e kopantsoeng le atomization

3.Atomization ea khase

4.Vacuum atomization

Lintlha tse qaqileng

| Motsoako oa phofo ea stainess % | |||||||||

| Kereiti | Cr | Ni | Mo | Nb | Cu | S | P | C | Si |

| 303 | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.15 | ≤1 |

| 304 | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 316 | 16-18 | 10-14 | 2-3 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303L | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304L | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316L | 16-18 | 10-14 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 317L | 18-21 | 12-16 | 3-4 |

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 314 | 24-27 | 18-21 |

|

|

| ≤0.03 | ≤0.04 | ≤0.2 | 1.5/2.5 |

| 310 | 24-26 | 19-22 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303LSC | 17-19 | 8-13 |

|

| 2 | 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304LSC | 17-19 | 8-13 |

|

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316LSC | 16-19 | 10-14 | 2-3 |

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410L | 11.5-13,5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 430L | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 434L | 16-18 |

| 0.75-1,25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434LNB | 16-18 |

| 0.75-1,25 | 0.4-0.6 |

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410 | 11.5-13,5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.25 | ≤1 |

| 420 | 12-14 |

|

|

|

| ≤0.03 | ≤0.04 | 0.25/0.35 | ≤1 |

| 430 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434 | 16-18 |

| 0.75-1,25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 440 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | 0.9/1.2 | ≤1 |

| 17-4PH | 15-17.5 | 3-5 |

| 0.15-0.456 | 3-5 | ≤0.03 | ≤0.04 | ≤0.07 | ≤1 |

| 15-5PH | 14-15.5 | 3.5-5.5 |

|

| 2.5-4.5 | ≤0.03 | ≤0.04 | <=0.07 | ≤1 |

Kopo

Stainless steel powder e ka sebelisoa bakeng sa ho fafatsa ka mocheso, metallurgy ea phofo, powder metallurgy press sintering (PM), injection molding (MIM) sintering filter, joalo-joalo, metsi a atomization ea oksijene<4000PPM, atomization ea khase<1000PPM.

Molemo oa HUARUI phofo ea tšepe e sa hloekang

● Esita le motsoako oa phofo, litšila tse fokolang

● Boima bo phahameng

● Oksijene e fokola

● Ho phalla hantle

●Bophahamo bo phahameng bo hlephileng, tekano e phahameng ea theipi

● phofo e nyenyane e sekoti, phofo e nyenyane ea sathelaete

Mokhoa oa ho laola boleng

1.Huarui e na le tsamaiso e tiileng ea tsamaiso ea boleng.Re leka lihlahisoa tsa rona pele ka mor'a hore re qete tlhahiso ea rona, 'me re leka hape pele ho thomello e' ngoe le e 'ngoe, esita le sampole.'Me haeba u hloka, re ka thabela ho amohela motho oa boraro ho etsa tlhahlobo.Ehlile haeba u rata, re ka u fa sampole hore u e hlahlobe.

2.Boleng ba sehlahisoa sa rona bo tiisitsoe ke Sichuan Metallurgical Institute le Guangzhou Institute of Metal Research.Tšebelisano ea nako e telele le bona e ka boloka nako e ngata ea liteko bakeng sa bareki.